Products

Our professional team works to increase productivity.

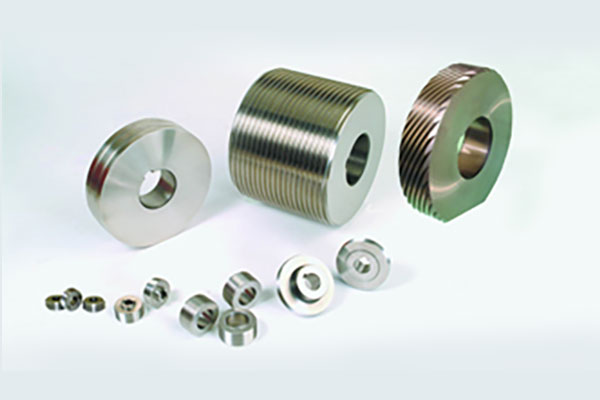

- For all thread and profile rolling machines (including multispindle automatic and CNC machines) upto MAX 200 mm diameter.

- For various types of thread rolling die heads (attachments), using 2 or 3 dies, for axial, tangential and radial rolling.

- For special applications like stainless steel and high tensile rolling.

- For infeed, annular throughfeed and combination throughfeed rolling.

- For all thread profiles as per ISO, BS, UN, DIN, ANSI as well as special profiles as per customer’s specifications.

- Regrinding of Dies along with suitable application based surface treatment.

1) Rolling Machine make and model

2) Rolling die dimensions: OD x Width x Bore; Keyway size

3)Component Thread size and tolerance

4) Component material to be rolled

5) Method of Rolling: Infeed or Throughfeed

- For all spline rolling machines upto MAX 300 mm diameter.

- For all Incremental spline rolling machines upto MAX 300 mm diameter.

- For Infeed and Axial force-feed rolling.

- For serration profiles as per DIN, IS, JIS, AISI standards as well as customer’s specified profiles.

- For involute splines of straight 2 helical type 30°PA onwards ,0.5 MOD

- For involute splines of 20° PA with stub tooth profile

- Regrinding of Dies along with suitable application based surface treatment.

1) Rolling Machine make and model

2) Rolling die dimensions: OD x Width x Bore; Keyway size

3) Component details: Module / Pitch, Number of Teeth, Pressure Angle, helix angle.

4) Component Profile details: Major diameter, Pitch diameter, Minor diameter, Root and crest radius, Over pin diameters along with pin diameter, Tooth thickness at PCD.

5) Component material to be rolled

6) Method of Rolling: Infeed or Force-feed.

- Serration and Thread milling cutters, bore and shank type, relief ground upto MAX 150 mm diameter.

- Form relieved cutters (including convex and concave radius with turned relief upto MAX 300 mm diameter.

- Rack Milling Cutters.

- Hobs for special applications.

- Screw broaches for steering nuts.

1) Cutter dimensions: OD x Width x Bore; Keyway size; Number of flutes.

2) Module / Pitch and Pressure Angle.

3) Component Profile or form details: Drawing to be enclosed.

4) Component material to be rolled.

- Ground worms upto MAX 100 mm diameter.

- Whirled worms upto MAX 50 mm diameter and Module 4.0.

1) Drawing of the Worm shaft mentioning profile details; Module, Pressure Angle, Number of Starts, Raw material, Hardness

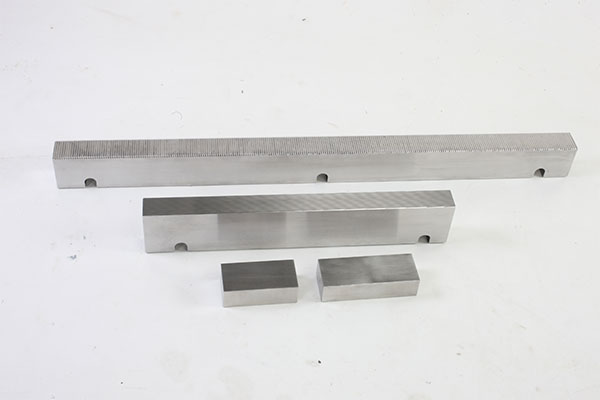

- Design- 2 Piece design.

- Material Used- M2 HSS

- Hardness Maintained : 62-64 HRC

- Length: 36”max (914.4mm)

- Width : 300mm ( 150mmx02nos)

- Module- 0.4M – 1.75M ( Subject to length of spline and no of teeth)

- Pressure Angle- 20° to 45°

- Helix Angle- 30°max

- Pitch Accuracies, Tooth to tooth- 0.005mm, Cumulative over 25 mm-0.02mm max, Cumulative ove250mm- 0.08mm max

- Tooth profile- Ground

- Edge Radius- Tangent as well as Spherical Radius

1) Design- 2 Piece design.

2) Material Used- M2 HSS

3) Hardness Maintained : 62-64 HRC

4) Length: 13”max (330.2mm)

5) Width : 200mm

6) Pitch- 0.8 MM – 4.0 MM

7) Pitch Accuracies, Tooth to tooth- 0.005mm, Cumulative over 25 mm-0.02mm max, Cumulative over 250mm- 0.08mm max

8) Thread profile- Ground